This past May (2024) we had a near catastrophic frame failure on our 1987 32S Avion. Thank goodness we found it and were able to get into a local welding shop within a day to have our frame on BOTH sides repaired.

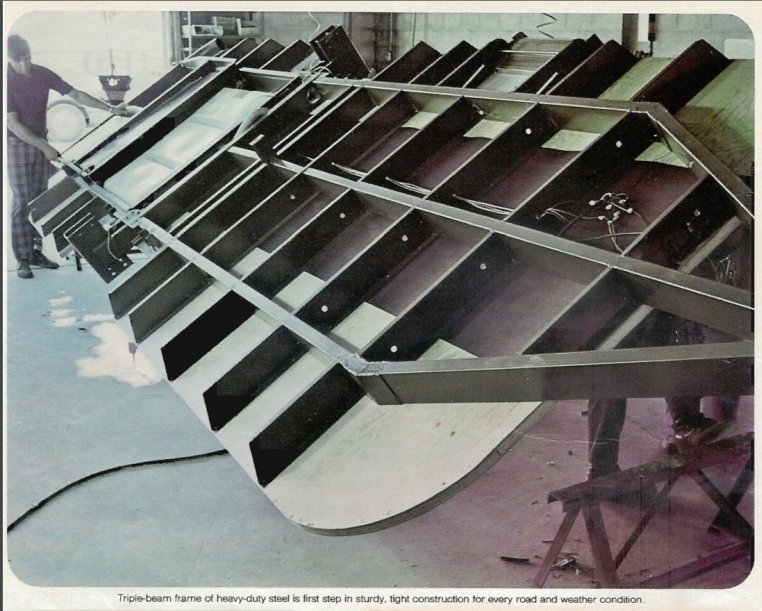

What truly saved us was the beefiness of Avion frames and it’s center beam construction! Most modern trailers do not use a center beam (see photo of an ’84 Avion frame below) **Note in the photo — below at the bottom left and top right you will see where the straight beam on each side, coming from the rear to front, then it takes a bend as it goes to the V of the hitch tongue area. See where there are welds and metal plates welded to secure those two areas. This is where our 1987, 32S Avion’s welds completely failed!

HERE IS HOW IT HAPPENED!

We had just been doing some routine cleaning of dust and dirt out of our two front most basement bays on the curb and street side. Kevin had previously cleaned and spray painted all the interiors of the bays with silver paint last year. He had seen no issues at that time.

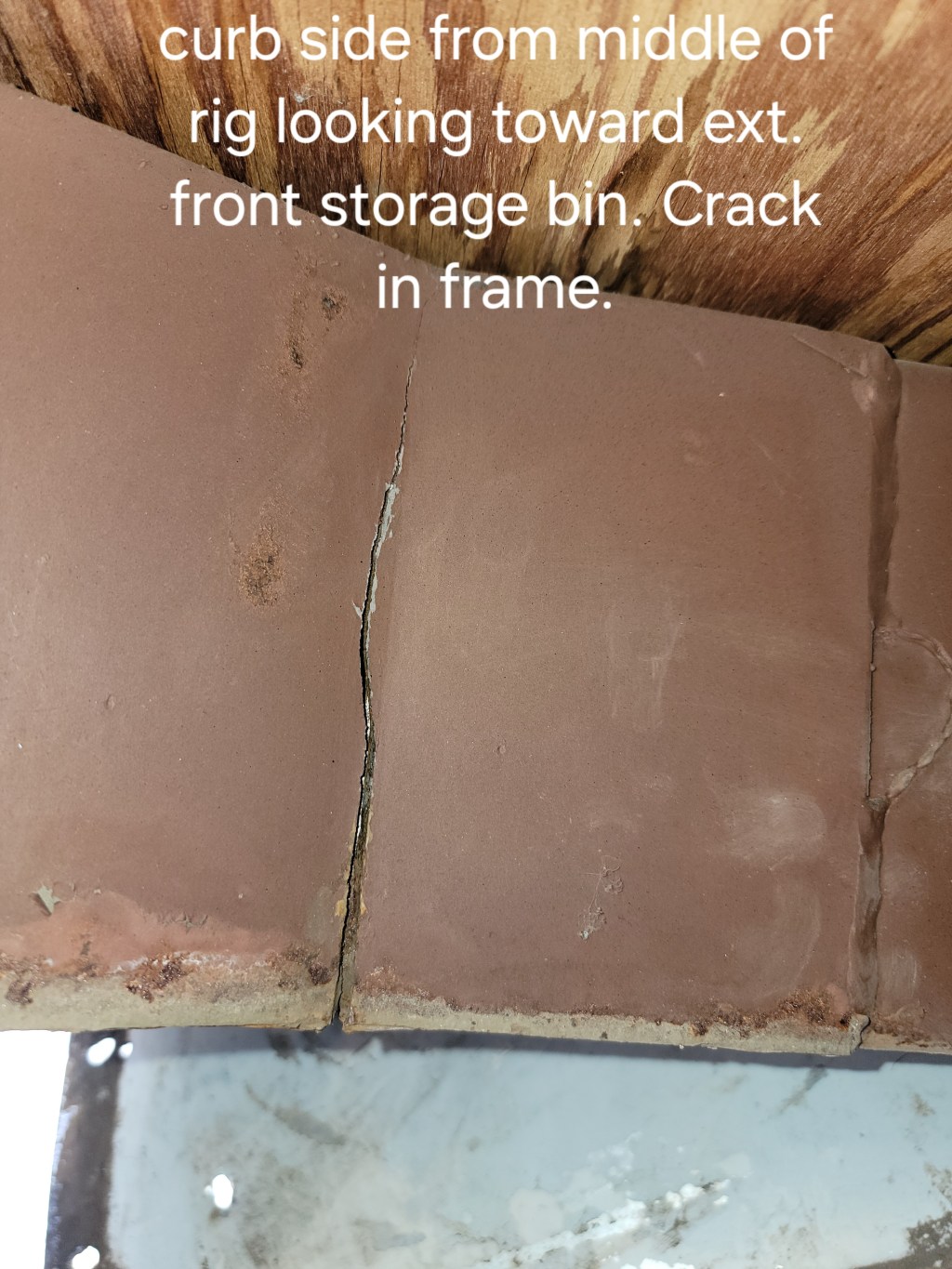

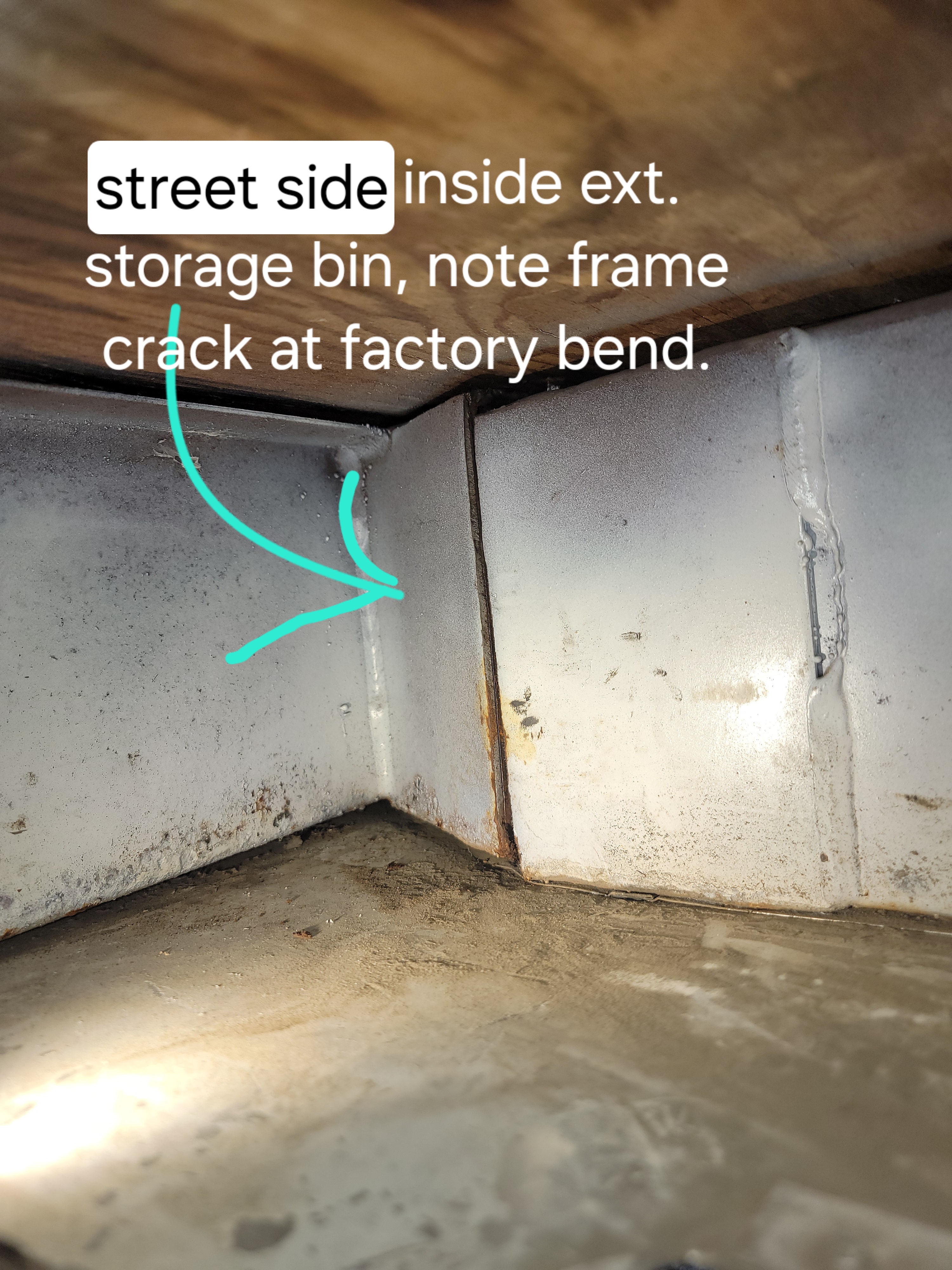

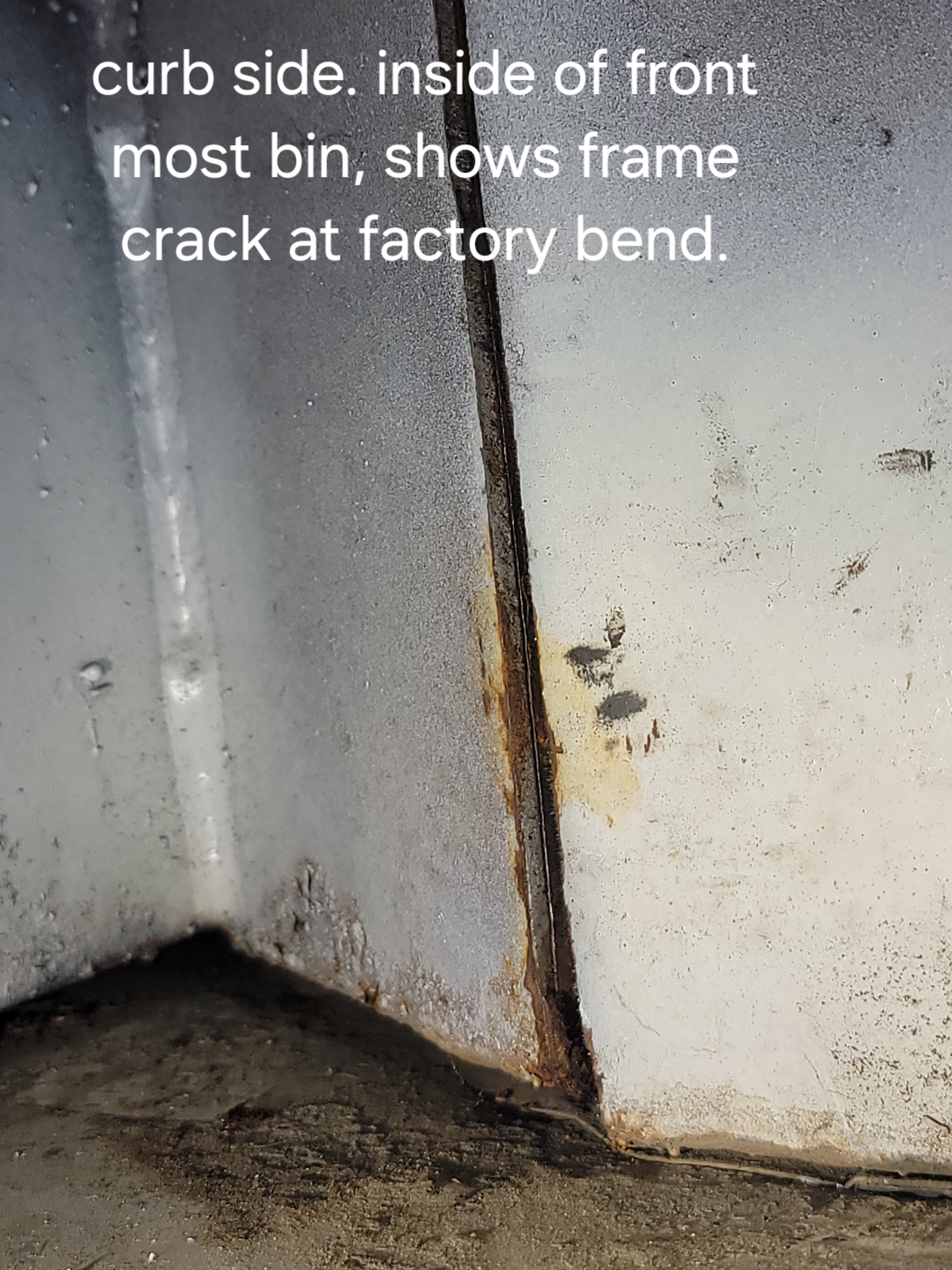

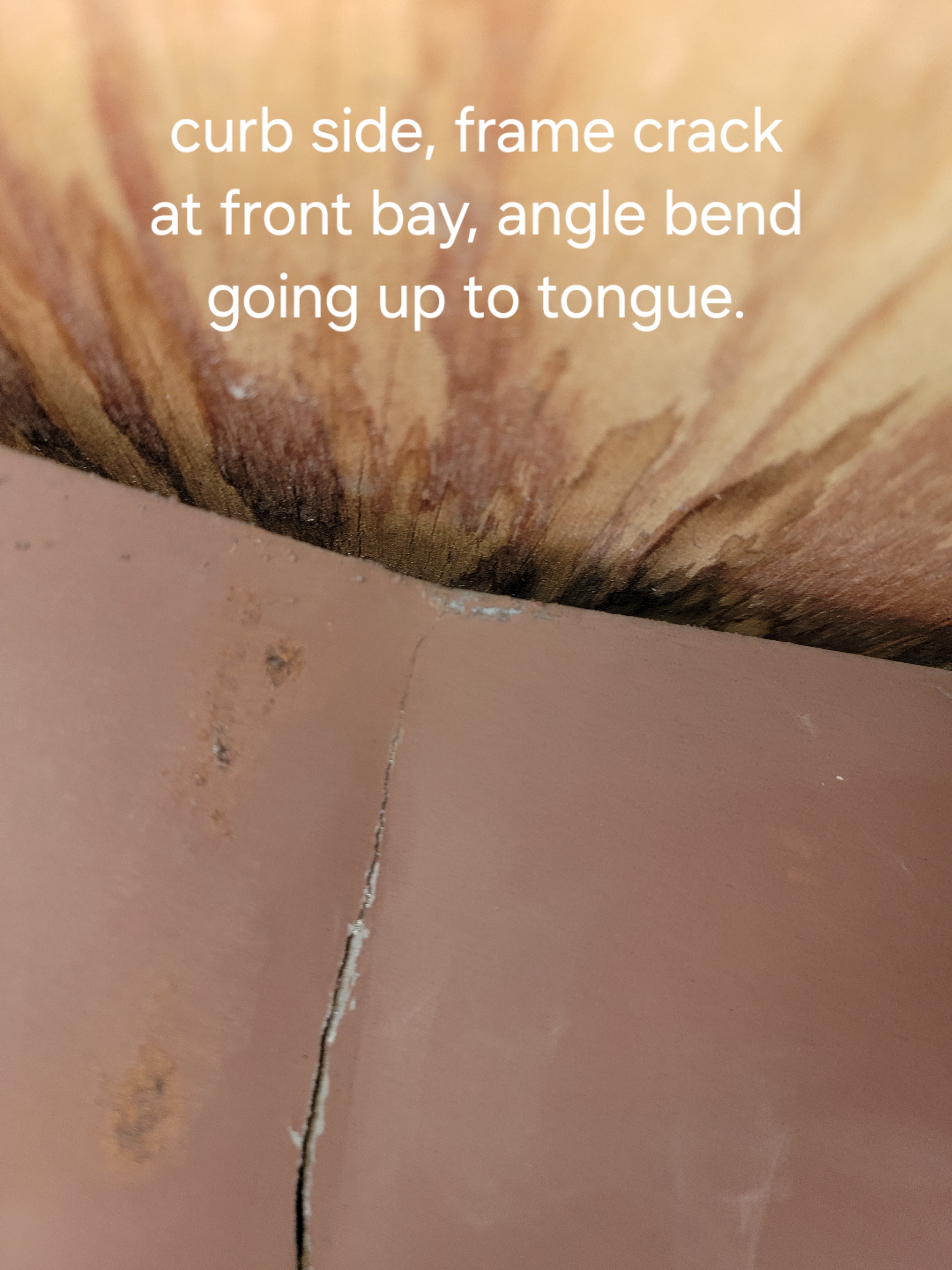

However, at this point in time (May 2024) he noticed the welded seam (the original) was showing a crack. This was seen on the curbside by looking in and to the front left corner of the basement storage bay by simply using a flashlight. On closer inspection, and after removing the belly pan in that area and crawling underneath to see the entire frame–there was also a break in the original plate and a break in it’s underlying weld. Here is a slide show showing photos of the weld and plate breaks. Use the arrow to scroll through to see both the curbside and street side frame breaks inside those front storage areas.

We called Chuck Cayo (Watervliet, MI) immediately (Avion repair guru we have used in the past with our ’73 and our ’87. Chuck’s dad worked with Avion’s and he is also the grandson of one of the original Avion manufacturers). Chuck confirmed that when these trailers were built they cut the straight steel side frame beams at that junction and welded it at an angle to bring that beam out to a V at the hitch coupler in front of the trailer. The seams were welded and plated there. (Refer to Avion frame photo at top of article) The two side beams meet up with the center beam and welded together and the hitch coupler then added on.

Indeed these welds and the plates themselves, after 37 yrs, had failed us.

We discussed the situation with Chuck and we concluded we do not know if this is an anomaly and rare or, that it is something inherent in this manufacturers design which over time, can fail on any model.

**THEREFORE It behooves all Avion owners to monitor these areas. Also, if doing a frame restoration you may wish to have additional plates welded on in these critical angle areas.

Some factors to consider in our somewhat unique situation which may not ever effect your Avion:

- We use a Hensley hitch and have since we purchased the Avion in 2020. It used the 1400# weight distribution Hensley bars. The prior owner to us also used a Hensley set up. We love how it handles sway and gives us a better turning radius and easier hookup. We believe now in hindsight that perhaps the 1400# bars were too much stress on the frame despite our overall weight specs that called for them (our rig is 10K#).

- We also had completed a 3-month tour of all over Alaska last summer, in total our trip from NY to AK to CA was over 16K miles. We know we did go over some quite rough roads, albeit at very reduced speeds and with care, but at no time did we recall experiencing any major issues that could have caused both side of the frame at this joint to spontaneously crack their welds. Even on good highways, etc. our we keep to 55-60 mph all the time.

- Last fall, we also had to do a very steep decline and pitch coming out of a campsite when in northern CA. This resulted in the trailer facing down a steep grade but the truck was on a flat road. We are leaning towards this as a contributor. See our video here of this.

- Could these have been factors? We will never know, but we welcome your thoughts.

We are just glad we caught the issue when we did. It could have ended in a catastrophic failure and major accident to our home on wheels-and us!

Could these factors be a reason for the failure of those welds? We don’t know for sure, and Chuck could not draw that complete conclusion either. Needless to say, after this repair was done now we have switched to the lighter 600#Hensley Weight distributing bars as a safety precaution. We also will avoid having to have such an steep angle coming out or going into a campsite.

When this fracture of the welds was found by Kevin we were at a campground just outside Gunnison, Colorado- about 3k miles into our trip from AZ to Glacier NP in Montana.

We limped the trailer gingerly to a local welding garage where they did an outstanding repair job taking us in the very next day. They allowed us to boondock in their lot the night before so we could be there when they opened in the morning. They worked on ‘our baby’ from 9 AM to 6 PM. They welded each crack on both sides then welded long 1/4″ steel plates on both sides sandwiching the angled frame areas completely reinforcing it securely. Here is another slide show showing those repairs both to both the seam and then with the additional plates welded to both sides of the frame.

We feel very secure in knowing this trailer will last another 37 years and so very thankful we found those cracks when we did. BTW-We normally keep lightweight outdoor light strands in there in plastic bags and don’t clean it out that frequently! Lesson learned-check these frame areas inside your storage bins!

Our total cost for this welding repair was only $660.00! That also included the welder installing a sleeve (we had purchased) where he welded it to the front of our side frame to hold our Hensley stinger piece when not in use. He also re-drilled a new hole on a hitch extender(for use with our bike rack for day trips) for our truck and filled in the original hole-so everything lines up perfect now! Nice custom work! We needed this done because of our Rockstar mud flap bumper system. Yes, we got a real deal on all of this. If you are ever need any welding done in the Gunnison CO are this is the place to go- Vulcan Ironworks. We cannot say enough about how awesome they were.

Check out this quick video of repair being done!

Here is a final photo of Kevin at the welding shop putting back in all the belly pan sheets after the repairs to the frame were done. The Pewter Palace is whole and running down the road to another adventure once more!

We sincerely hope this NEVER happens to anyone else’s Avion or any trailer for that matter. We realize how truly lucky we were to catch this frame failure.

We hope our experience will help others to know what to look out for and what to avoid as well. Wishing you all safe travels and as always we welcome your comments, suggestions and appreciate it if you would subscribe to our blog and our YouTube Channel.

Until we meet on the road….safe travels!

Leave a comment